Portfolio

CLARO

Chemical Analyzer

Chemical Analyzer

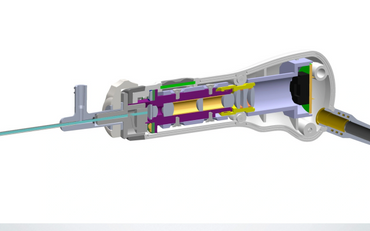

Handheld medical device for the treatment of acne

This compact device packed small intricate components into a small, ergonomic package. Our involvement included designing the injection-molded parts with snap fits and ultrasonic welding, reviewing the tool design, writing production documentation including assembly instructions, and assisting with production startup. The small startup, our client, was bought by a larger company due to their successful product launch.

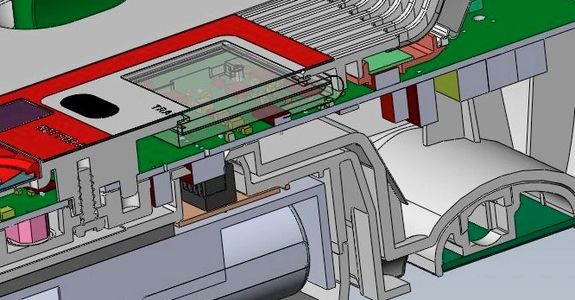

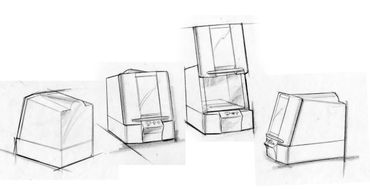

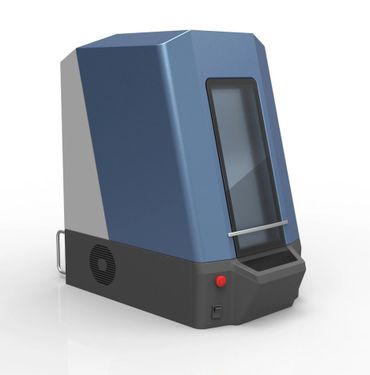

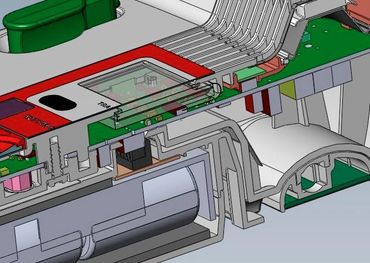

Chemical Analyzer

Chemical Analyzer

Chemical Analyzer

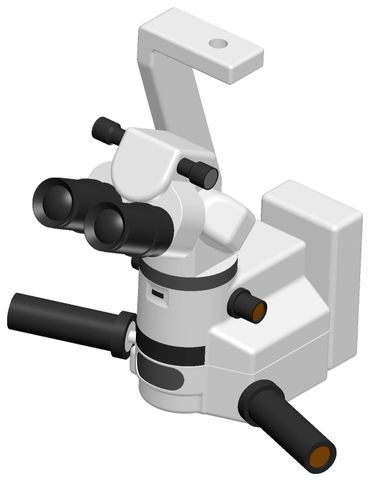

A large instrument for labs and research institutions

Our team handled mechanical engineering for an instrument to run biochemical assays in a lab environment. We did all mechanical engineering except for the fluid handling, which the client’s team developed internally. We designed moving mechanisms, incorporated the electronics and a microscope, and engineered the outer housings based on industrial design by ByDisegno Advanced Thinking LLC. The product was successfully shown at an important trade show and helped the client secure a long-term contract.

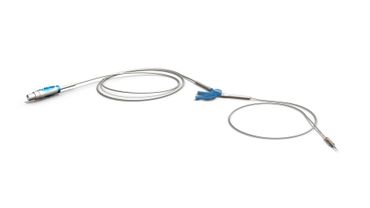

Training unit simulating use of a portable medical device

Training unit simulating use of a portable medical device

Training unit simulating use of a portable medical device

Mechanical Engineering of entire device

Our team has had a long-term relationship with a medical device manufacturer with about $100m in annual revenue. We recently designed a training device for them, incorporating existing electronics into new plastic housings. The device involved a spring-loaded lid mechanism that we had to fine-tune to achieve a good motion, as well as a removable battery pack and a remote control. We designed buttons, a connector, and incorporated a speaker and a display.

TRUFIG

Training unit simulating use of a portable medical device

Training unit simulating use of a portable medical device

Mechanical Engineering of new iPod wall-mounted dock and new HVAC product line

We designed two new products for a home-electronics client focused on high-end homes. The first one is an in-wall iPod dock to control home audio equipment. The second is a whole line of HVAC vents of various sizes. What’s remarkable about these is that they are completely flush to the wall: they are adjustable to allow for wall imperfections, and maintain a 0.5mm gap all around the face of the vent. The idea here, of course, is to hide these grilles as much as possible, particularly in very modern homes. Our contribution is towards the end of their catalog.

We’ve had many, many other projects, but these are some of the more interesting ones. We designed the labels for a life-saving medical device being launched in Japan (in Japanese, of course), we’ve done packaging design (and overseen testing), parts welded with ultrasonics, snaps, parts with strict ingress-protection issues (up to IP55), etc. A few months ago we took 3D models from a local ID firm and did all their 2D documentation – without a single in-person meeting. We even have an in-house 3D printer for quick prototypes.

Photo Gallery

Client List